|

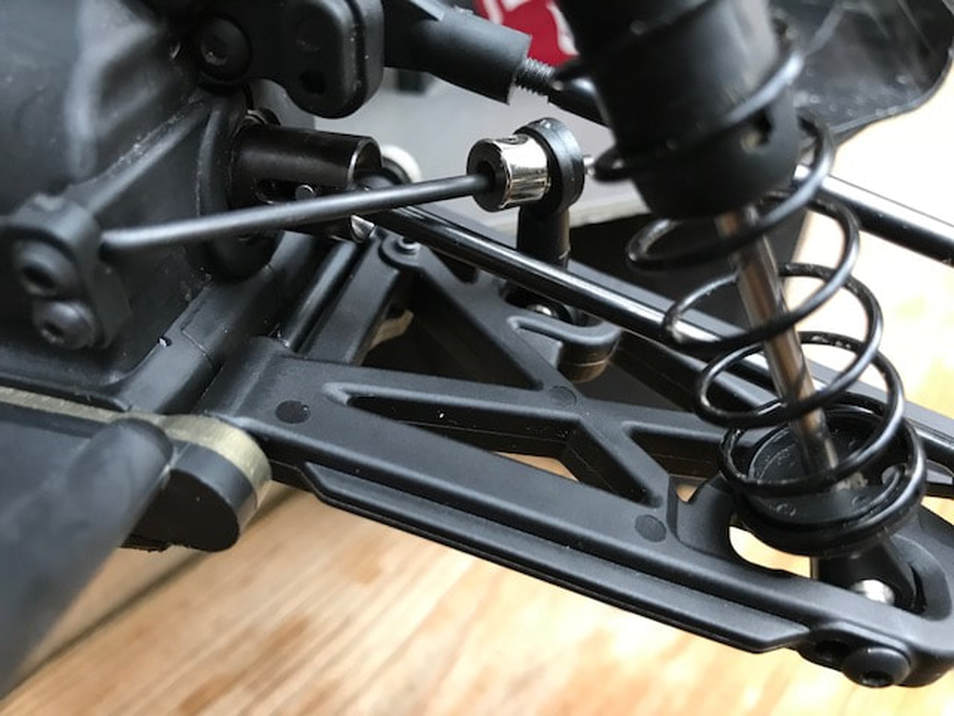

I have started to tear my TR-SC10E down in preparation for an upcoming race and while I was cleaning it, I decided to add a few more upgrades. I started at the rear of the truck with the following parts: The TM-65 Anti-Roll Bar was a relatively straight forward installation. I had the rear clip removed from the truck and the rear bumper removed from the clip so access to the mounting points was simple. The TR-SC10E factory set-up does not include an anti-roll bar (sway bar). Having been a "basher" all of my life and not a racer, I'm not sure yet what the effects of adding an anti-roll bar will be. The track I run on is a somewhat rough, outdoor track with decent traction. I wouldn't call it loose nor would I call it a high bite track. I've noticed my truck is leaning as it goes through the sweeper so I'm thinking that adding the anti-roll bars front and rear may give me more stability through this long turn. I found this Adam Drake tutorial video to be very helpful in the installation and set-up my anti-roll bar. The TMS-08 Universal Drive Shafts were also a simple drop-in installation. The stock dogbone configuration was working fine but when I removed the stock dog bones, I noticed some wear. Rather than install new dogbones, I opted to go with the Universals. They operate very smoothly and quietly so I'm sure I'll keep them installed. I did some quick research on dogbones vs universal joints and it seams some folks like to use dogbones on rough tracks and universals on smooth or high bite tracks. I don't have the skills to tune my truck this closely so will try the universals simply because I like how smoothly they operate. The TMS-25 Aluminum Wheel Hexes are another item I had set aside for website photography and just couldn't resist the temptation to install these on my truck. I hadn't had any problems with the stock plastic wheel hexes but while my truck was torn down, I figured now would be a great time to add these as well. They look great and I'm sure they will be durable. The only potential week point I can see with these is the rubber o-ring that secures the drive pin. I may try to source some replacement o-rings so that I can replace these from time-to-time. Last but not least, I did a quick clean and rebuild of the stock plastic shocks. I filed off a small amount of flashing left over on the outside of the shock bodies from the molding process to ensure a nice, smooth surface for the shock springs to travel across then filled them with Associated 45wt oil. I intend to install the aluminum shocks at some point but for now, I decided to stick with the stock shocks as they are functioning well and not leaking. What would I do differently next time: Generally, I think it's a good idea to only make one change then test the results before making any additional changes. I didn't take my own advise this time and made a few changes that will effect the handling of my truck and it may be difficult to pin point what improved (or not) and why. The rear suspensions feels rather stiff but I'm not sure if this is due to the addition of the anti-roll bar or the 45wt shock oil. If I was to do this over again, I'd rebuild the truck and only change the shock oil. I'd leave the anti-roll bar for another day. Oh well...I'll have to see how the track testing goes later this week. By the way, if you liked this post, please check out my other TR-SC10E modifications below and of course, you can support me by purchasing your TR-SC10E parts and hop-ups from me and also by using my Amazon links if you make any purchases at Amazon (they'll pay me a small commission)

Part 1 - New Body Part 2 - ESC Mount Part 3 - Front Bumper Part 4 - Wheel Nuts Part 5 - Aluminum Rear Hubs and Aluminum Steering Knuckles 'till next time Rob Comments are closed.

|

TOP Categories |

information |

resources |

|

|

© www.teamredcatshop.com All rights reserved